HYPERSPECTRAL IMAGING TECHNIQUE AS A STATE OF ART TECHNOLOGY IN MEAT SCIENCE

1Necmettin Erbakan University, Seydişehir Vocational School, 42090, Seydişehir, Konya, Turkey

2Selçuk University, Agricultural Faculty, Department of Food Engineering, Selçuklu, Konya, Turkey 3Necmettin Erbakan University, Department of Management Information Systems, Selçuklu, Konya, Turkey 4Necmettin Erbakan University, Department of Food Engineering, Meram, Konya, Turkey

*Corresponding author: [email protected]

Article History: Received on 20th December 2015, Revised on 30th January 2016, Published on 20th June 2016

Abstract

As it‟s well known, there is an important interactive relationship between technology and industry. Some new technology can lead to build new industry or a new developed technology may be damageable for the present industry. So, competition and economic challenges are forcing people to find a new way to survive as well as food producers and food industry.

Food is one of the most important and most fundamental desire in human life and it‟s affecting people‟s livelihood. People can change most of their choices and these choices can directly affect the industries such machine industry, chemical industry, construction industry etc. but food industry is always popular due to it is a part of human life. However, competition is increasing day by day thus food manufacturers invest more money and time for new technologies.

So a new term is composed under the name of “modern food industry”. This industry is quite complex and very important because it supplies most of the food consumed by the world population.

Recent years, the modern food industry is trying to find some new technology to achieve high efficiency and low-cost product as well as high quality and safe food. Food safety, nutrition and food security are inextricably linked. Unsafe food creates a vicious cycle of disease and malnutrition, particularly affecting infants, young children, elderly and the sick.

According to a report of World Health Organization (2015), an estimated 600 million – almost 1 in 10 people in the world – fall ill after eating contaminated food and 420 000 die every year, resulting in the loss of 33 million healthy life years (WHO 2015).

This shows how food safety and quality is important. Quality and safety of food are usually defined by physical attributes (e.g., texture, color, marbling, tenderness), chemical attributes (e.g., fat content, moisture, protein content, pH, drip loss), and biological attributes (e.g., total bacterial count). Traditionally, assessment of quality and safety involves human visual inspection, in addition to chemical or biological determination experiments which are tedious, time-consuming, destructive, and sometimes environmentally unfriendly. These necessitate the need for accurate, fast, real-time and nonchemical detection technologies, in order to optimize quality and assure safety of food (Huang et al. 2014).

With recent advancements in computer technology and instrumentation engineering, there have been significant advancements in techniques for assessment of food quality and safety. Machine vision and NIR spectroscopy are two of the more extensively applied methods for food quality and safety assessment. Machine vision techniques based on red-green-blue (RGB) color vision systems have been successfully applied to evaluate the external characteristics of foods (Chao et al., 1999; Lu et al., 2000; Tan, 2004; O'sullivan et al.;2003; Faucitano et al; 2005; Huang et al., 2013a).

HSI is based on remote sensing applications (Goetz, 1985). By this technique, spectral and spatial information of sample can be obtained from 300 – 2,600 nm wavelength) (Bannon, 2009). The main difference of the HSI from other spectrographic measurements is getting more information from an object thus this technique is being used in several fields (Huang et al., 2013b; Lara et al., 2013; Gendrin et al., 2007; Cruz et al., 2009; Garcia-Allende et al., 2008). It‟s possible to determine food quality and safety by detection of microbial contamination (He and Sun, 2015), detection of contaminations (Yao et al., 2013; Kim et al., 2004), prediction and visualization of chemical composition (Kamruzzam et al., 2012), identification of defects (Xing et al., 2005; Nagata et al., 2006), quantification of constituents (Qiao et al., 2007) and even fecal contaminant detection (Park et al., 2006).

As well as food producers and food researchers have begun to show interest in the HSI technology. (Huang et al. 2014) reported that in the early 2000s, the scientific articles about HSI were started to publish and today nearly 250 articles are publishing.

In this paper, usage of hyperspectral imaging systems in meat and meat products is reviewed. Since hyperspectral imaging technique is being used, it‟s being developed by solving the issues. It became known that HSI technology is suitable for many foods especially for meat and meat products. The mechanism and some of other details were reported in some of other published review articles. So, the scope and the focus of this paper is recent advances of the usage of HSI in meat and meat safety, meat microbiology, meat defection, prediction of meat chemical properties etc.

There are so many factors that affects consumer behavior. In a study of Font-i-Furnols & Guerrero (2014), the main factors and sub- factors were determined for the consumer behavior as in shown in Figure1. However, these factors are quite complex and connected with each other. For meat and meat products, visual appearance characteristics (i.e., color, fat content, marbling, drip loss) are intrinsic quality cues highly related with consumers' expectations of meat quality (Banović et al., 2009; Bredahl et al., 1998; Verbeke et al., 2005) and their choice at the point of purchase because these characteristics are used to assess food quality (Banović et al., 2012; West et al., 2001).

On the other hand, beside consumer behavior, there are some well-known external conditions for meat consumption such health concerns, religious reasons, negative propagandas, culture, financial difficulties, regulations, imitation and adulteration, political reasons etc. But however, a study on estimation meat consumption in future (Delgado, 2003) demonstrated that meat and milk consumption will expand in future. Table 1 shows the estimated consumption of meat and milk in year 2020.

Projected annual growth 1997–2020 | Total consumption in 2020 | Per capita consumption in 2020 | ||||

Region | Meat | Milk | Meat | Milk | Meat | Milk |

(%/y) | (million metric tons) | (kg) | ||||

China | 3.1 | 3.8 | 107 | 24 | 73 | 16 |

India | 3.5 | 3.5 | 10 | 133 | 8 | 105 |

Other East Asia | 3.2 | 2.5 | 5 | 2 | 54 | 29 |

Other South Asia | 3.5 | 3.1 | 7 | 42 | 13 | 82 |

Southeast Asia | 3.4 | 3.0 | 19 | 12 | 30 | 19 |

Latin America | 2.5 | 1.9 | 46 | 85 | 70 | 130 |

of which is Brazil | 2.4 | 1.8 | 20 | 30 | 94 | 145 |

only | ||||||

WANA | 2.7 | 2.3 | 13 | 42 | 26 | 82 |

Sub-Saharan | 3.2 | 3.3 | 11 | 35 | 12 | 37 |

Africa | ||||||

Developing | 3.0 | 2.9 | 217 | 375 | 36 | 62 |

world | ||||||

Developed world | 0.8 | 0.6 | 117 | 286 | 86 | 210 |

World | 2.1 | 1.7 | 334 | 660 | 45 | 89 |

Sources: Total and per capita meat consumption for 1997 are annual averages of 1996–1998 values, calculated from the United Nations Food and Agriculture Organization database (FAO), 2002 (11). Projections are from the July 2002 version of IMPACT.

1Consumption is direct use as food, uncooked weight bone-in. Meat includes beef, pork, mutton and goat, and poultry. Milk is milk and milk products in liquid milk equivalents. Metric tons and kilograms are 3-y moving averages centered on the year shown. WANA is Western Asia and North Africa.

The last few decades, more and more countries are embarking on higher consumption of livestock products, making a shift in their daily diet towards a western approach. Focusing on red meat, the global annual consumption per capita is forecast to reach 45.3 kg, on average, by 2030 (i.e., twice as high as the respective assessment during 70 s)(WHO, 2016); while in a recent estimation regarding Mediterranean area, a range from 77 to 90 kg individual red meat intake per year was highlighted (FAO, 2015). Indeed, red meat and its products are highly preferable food items due to their energy, macronutrient (i.e., protein and fat) and salt content, nutritional characteristics which contribute to tastefulness and satiety; whereas regarding its micronutrient profile, a wide range of minerals (i.e., heme iron, zinc) and vitamins (i.e., vitamin A, Β12), reasonably make it an important source of essential substances for human beings (McAfee et al., 2010).

Meat and meat products are an important source of protein in human diets, and their consumption depends on socio-economic factors, ethics or religious beliefs, and tradition. Globally, pork is consumed the most (15.8 kg/capita/year), followed by poultry (13.6 kg/capita/year), beef (9.6 kg/capita/year) and finally sheep and goat meat (1.9 kg/capita/year) (FAOSTAT, 2014).

The nutritional components of the meat are minerals, fats and fatty acids, vitamins and other bioactive components, and small quantities of carbohydrates. Meat has approximately 25% dry matter and has some the most important ingredients for human health

such essential amino acids and bioavailable vitamins also minerals. Another aspect for the meat consumption may be that there is a correlation between meat consumption and developing for the countries. There are several studies that shows meat consumption may maintain success on several parts of human even in school and scientific evidences also confirm this(Mann 2000, Neumann, 2007, Webb 2005). Of course the main recommendation is based on a balanced diet that includes meat consumption.

There are also various studies that recommend lower meat consumption in diet but the choosing which food is beneficial depends on people‟s conditions, culture, economical factors, environmental factors etc. Furthermore, in a report of FAO (2015), it was indicated that the meat consumption had been relatively static in the developed world, annual per capita consumption of meat had doubled since 1980 in developing countries. In this report, it was also pointed out that world meat production was projected to double by 2050, most of which was expected in developing countries. The growing meat market provides a significant opportunity for livestock farmers and meat processors in these countries. It was also remarked that increasing livestock production and the safe processing and marketing of hygienic meat and meat products may represent a big challenge.

Today, it‟s known that one of the most foodborne illness source is meat and meat products (Todd, 1996). As it‟s explained before, risks such imitation and adulteration are awaiting us and this will continue to grow up with new un-known/ unpredictable issues day by day and year by year. So some of food researchers have focused on determining the quality by basic, rapid, non-dangerous and non-destructive methods to achieve these issues. So, the latest technologies may contain machine vision online measurements (Patel et al, 2012), NIR spectroscopy (Osborne, 2006), electronic nose measurements (Ghasemi-Varnamkhasti, 2009), colorimetric sensors measurements (Zaragozá et al. 2012), acoustic measurements (Davies, 2014), sensor fusion measurements(Cimander, 2002), x-ray measurements (Lim and Barigou, 2004), raman spectroscopy technique (Zheng and He, 2014), nuclear magnetic resonance (Marcone et al, 2013), terahertz spectroscopy/imaging(Qin et al, 2013) and hyperspectral imaging technology(He and Sun, 2015).

All of them have some advantages and disadvantages such difficulty, cost, mobility, volume, health risk etc. and most of them are today‟s technology. But Hyperspectral imaging is not only quite enough to solve these problems but also may contribute the manufacturer by giving more and more information about the product as it explained in next part of this paper.

Hyperspectral imaging technique is non-destructive, real-time and easy-to-use detection tool for food quality and safety and it‟s suitable for the continuous production. One of the major factor is no need to any chemical and no risk on the perspective of occupational health and safety. Another attractive fact is one-time installation and long-time usage so indirectly low-cost but high efficiency. This technique may be used for most of food. But it can be considered a major advance for the meat and meat products. As it clearly known that meat has some issues such as short shelf-life, expensiveness, difficulties on storage, easy and rapid degradability, difficulties on transportation etc. but consumers always desire high quality of meat and meat products. The need of modern meat industry is modern technique that serves a solution to most of the meat production problems.

Generally, meat quality can be defined in terms of consumer appreciation of texture and flavour, and food safety, which includes the health implications of both compositional and microbiological properties.

The meat industry is currently undergoing dramatic changes in applying the most advanced technological inventions that have gained acceptance and respect in handling, quality control and assurance, packaging, and distribution (Shackelford et al., 2004). The changes are noticed in many fields because there is an increasing demand from the consumers and the media for optimal quality, consistency, safety, animal welfare, and environmental issues.

Many different methods for measuring meat quality traits are available which are based on different principles, procedures, and/or instruments. Over the past few years, a number of methods have been developed to objectively measure meat quality traits (Abouelkaram et al., 1997, 2006; Liu et al., 2003; Shackelford et al., 2005; Vote et al., 2003). One of these methods is the imaging technique that has been applied for visual evaluation of meat quality. On the other hand, the spectroscopic technique is finding increasing use owing to its rapidity, simplicity, and safety, as well as its ability to measure multiple attributes simultaneously without monotonous sample preparation. However, the spectroscopic technique alone is not able to provide some fundamental information where demonstration of the spatial distribution of quality parameters is essential. Hyperspectral imaging has thus emerged to integrate both the spectroscopic and imaging techniques for providing spectral and spatial information simultaneously to cope with the increasing demand for safe foods. Hyperspectral imaging technique is an upcoming and promising field of research for non-

destructive quality assessment of agricultural and food products including meat (Cluff et al., 2008; Naganathan et al., 2008a, 2008b). In recent years, there has been growing interest in this technology from researchers around the world. The main impetus for developing hyperspectral imaging system is to integrate spectroscopy and imaging techniques to make direct identification of different components and their spatial distribution in the tested sample. The commercial growth of hyperspectral imaging lies in its ability to solve some application problems, such as those associated with industrial process monitoring and control, diagnosis, inspection, and quality-related assessments. Although this technology has not yet been sufficiently exploited in meat processing lines and quality assessment, its potential is promising. In contrast to conventional methods for the determination of meat quality parameters, the hyperspectral imaging technique is a sensitive, fast, and non-destructive analytical technique with simplicity in sample preparation allowing simultaneous assessment of numerous meat properties. For instance, hyperspectral imaging can be used to identify a particular type of meat (Qiao et al., 2007a, 2007b), as some meat (species, cuts or grades) are more valuable for the consumers than others (Alomar et al., 2003). Some other key potential applications include overall inspection and disease detection in different meat products (Chau et al., 2009; Kim et al., 2004;Wold et al., 2006). In addition, hyperspectral imaging can be used as an authentication tool in order to prevent fraud as well as to estimate chemical composition with acceptable accuracy and even to detect handling aspects of the product. Therefore, developing a quality evaluation system based on hyperspectral imaging technology to assess meat quality parameters and to ensure its authentication would bring economic benefits to the meat industry by increasing consumer confidence in the quality of the meat products. In this chapter an overview of the current meat quality assessment techniques is provided with an emphasis on hyperspectral imaging method. In particular, latest research results on using hyperspectral imaging technology for assessing quality of red meat (beef, lamb, and pork) and white meat (poultry and fish) will be highlighted and described in more detail.

Hyperspectral imaging technique may be defined as : it is a technique that generates a spatial map of spectral variation, making it a useful tool in many applications. (ElMasry & Sun 2010) or Hyperspectral imaging which was originally developed for remote sensing applications can be used to obtain spectral and spatial information of an object over the ultraviolet, visible, and near-infrared spectral regions (300 nm–2,600 nm)(Bannon, 2009) or an upcoming and promising field of research for non-destructive quality assessment of agricultural and food products including meat (Cluff et al., 2008; Naganathan et al., 2008a, 2008b).

A typical hyperspectral imaging system mainly consists of a spectrograph, a camera with lens, an illumination unit, a moving table driven by a motor and a computer installed with image acquisition software (Figure 2). By scanning with such system, a hyperspectral image of a food product is acquired and used as a basis for further product quality evaluation and assessment. The hyperspectral image is a three-dimensional (3-D) “hypercube” or “datacube” (x, y, λ), in which (x, y) represents two-dimensional (2-D) spatial information and λ represents one-dimensional spectral information. The 3-D “hypercube” can be described either as 2-D images (x, y) at each one- dimensional wavelength (λ) or as spectra (λ) at every image pixel (x, y) (Sun, 2010). As an example, a salmon fillet was first placed on the moving table of hyperspectral imaging system (900–1700 nm) to be scanned at a speed of 2.8 cm/s line by line using 10 ms exposure time to create a hyperspectral image shown in Figure 3. The raw hyperspectral image of the salmon fillet is comprised of a series of contiguous spatial sub-images (x, y) at every individual wavelength (λ) . Each sub-image presents the spatial distribution of spectral information at each wavelength. At a certain wavelength, spectral intensity at different locations within an image reflects the different light absorption, which is due to the different distribution of salmon flesh compositions and is difficult to be observed in RGB image. With such spectral and spatial information, some physiochemical compositions of salmon flesh such as moisture (He, et al., 2013), fat (Segtnan et al., 2009), tenderness (He et al.,2014a), pH (He et al., 2014b) and color (Wu et al., 2012) can be quantitatively predicted and visually observed simultaneously, which however cannot be realized by spectroscopy or imaging technique alone.

Lately, while the popularity of hyperspectral imaging is increasing, this also caused attract attention for some big companies. Before this, there were only a few companies can design the system. It was a difficulty for both researchers and meat industry. But today, there are several companies that provide to build the system.

Another issue about this technology is configuring the system. It might be difficult to configure the system for the products. But recently, so many studies are available to help people which system and configuration is suitable for their purpose. The factors that directly associated with the system are the true camera type, spatial resolution, calibration method and spectrograph.

Some of recently studied are summarized and it would be necessary to investigate all of studies deeply to understand the system.

Cheng et al., (2016) studied on a freshness prediction of grass carp fish fillet by using multispectral imaging system. They used successive projections algorithm (SPA) and genetic algorithm (GA) for the purpose of getting highly information from the samples to predict the freshness. In the study, researchers were used five different wavelengths (432, 550, 660, 820, 965 nm) for the SPA and six different wavelengths (435, 565, 660, 815, 870, 970 nm) for GA. As a result of their study, the developed real-time and on-line multispectral imaging system was feasible and practical in quality evaluation and control of grass carp by a successful prediction of TVB-N, TBARS and K value.

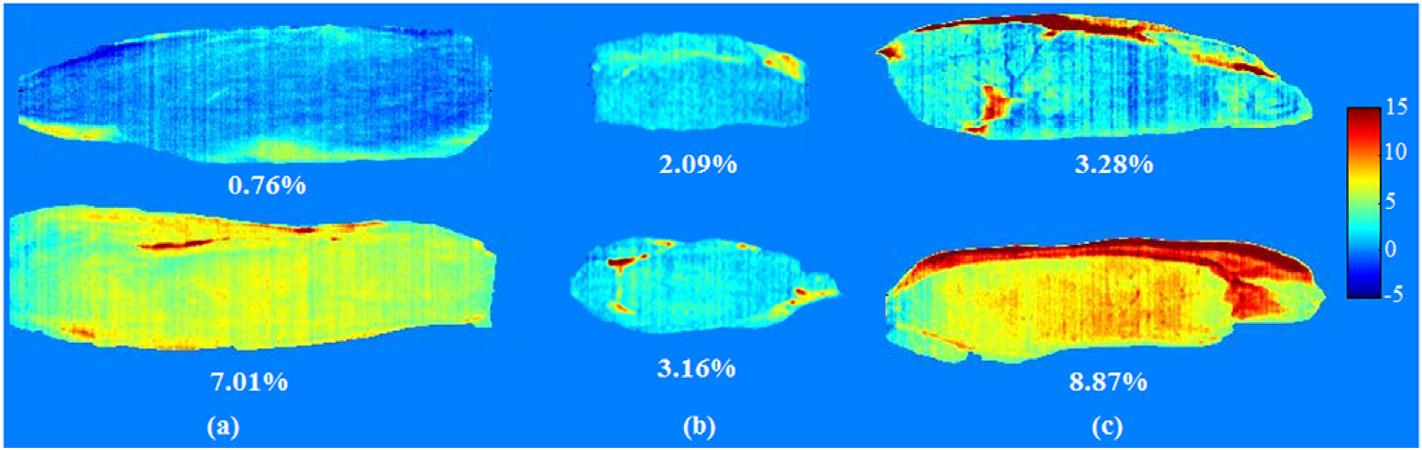

In another study, predicting water holding capacity is purposed by using the hyperspectral imaging system in red meat. The used spectral range was 400-1000 nm to getting information from red meat samples. They developed an algorithm that was used for the sample images. As in seed in Figure 4., researchers showed some distribution maps of the tested samples. The recommendation of the researchers were WHC may be predicted successfully by using eight wavelengths (545, 610, 705, 765, 805, 900, 940, and 970 nm) and this can be modified by low cost (Kamruzzaman et al. 2016a).

Antonio et al. (2016) studied on four different lamb muscle (Longissimus dorsi, Psoas major, Semimembranosus and Semitendinosus) discrimination which is important for the meat industry due to price by using hyperspectral imaging system. The used spectral range was 380 – 1028 nm. They compared various machine learning algorithms. They mainly aimed for muscle classification and gained correct classifies at a ratio of 96.67% in the 30 samples. It also indicated that the Artificial Neural Networks, namely the linear Least Mean Squares (LMS) was the most successful method when it compared with other 6 machine learning algorithms.

Khulal et al. (2016) also studied on prediction of total volatile basic nitrogen (TVB-N) content in chicken using hyperspectral imaging (HSI) technique. In order to achieve high accuracy and success they also used and combined different data dimension reduction algorithms. Researchers used Principle component analysis (PCA) and Ant Colony Optimization (ACO) for data dimension reduction and the back propagation artificial neural network (BPANN) algorithm for modeling. They indicated that HSI integrating spectral and spatial information may have a high potential in quantifying TVB-N content of chicken.

In another study of Kamruzzaman et al. (2016b) the real-time monitoring of moisture in red meat by using hyperspectral imaging was purposed. The used spectral range was again 400-1000 nm. They selected 10 wavelengths (440, 480, 575, 620, 655, 680, 725, 780,

955, from the full spectral range of 121 wavelengths. As an important part of success indicator, an on-line image was showed in Figure 5. They indicated that the multiple linear regression (MLR) model is suitable in predicting moisture content, with R2p of 0.97.

P

A similar study was conducted by Ma et al. (2016) which aimed to predict moisture content in pork samples prepared in different conditions including fresh, frozen–thawed, heated– dehydrated and brined–dehydrated by using HSI techniques. They obtained good results for the optimized partial least square regression (PLSR) model (R2P= 0.952) and the optimal wavelengths selected by regression coefficients (R2 = 0.966).

It‟s estimated that there are more than 370 articles published in SCI or SCI-Expanded Journals that are related to using hyperspectral imaging (HSI) for evaluating meat and meat products. When additional indexed journals are taken into account, these estimates increase to more than one thousand. Until 2010, there were less than 70 of these types of related publications, showing this technology is rapidly garnering attention from researchers. Such attention can be attributed to its high efficiency in procuring results, while maintaining low production and analytical costs. Likewise, its ability to be easily operated provides a healthier and safer work environment, an advantage that cannot be overlooked.

The use of hyperspectral imaging creates a near perfect database for each food item. When the HSI system is used in conjunction with food production systems, the quality of the data stored is by far superior to the randomly analyzed sampled method.

As previously mentioned, the growing trend of “low-meat consumption” is in part due to health concerns, but equally so, due to financial reasons. Meat is one of the most important and essential food sources for people and there is yet be evidence that high quality and wholesome meat or meat products cause a health risk for individuals. On the contrary, it is of extraordinary importance especially for children under 15 years of age in developing countries. The trend of low-meat consumption grew as a result of food commodities, including meat and meat products, having always been vulnerable to fraudulent admixture or adulteration with cheaper inferior materials. In this context, there is an interesting difference between developing and developed countries. The consumers who live in richer and developed countries have the option of choosing locally produced food products which is considered a safer alternative. In contrast, people who live in the poorer or developing countries, have limited selections and often resort to buying food which are produced by a popular company or brand name they trust, given that these foods are safer than those produced locally. It is clear that the concern of food safety for the consumer is being increased day by day when we consider that their knowledge is mostly based on what they learned from their family members, internet, the media (television, radio and newspapers), and occasionally from government publications.

There are many aspects of this issue to still be considered. The Hyperspectral Imaging System in comparison to other alternatives, may be the most efficient and adaptable to solving these issues. Hence, its technology is suitable for not only in large production

systems, but furthermore for smaller systems including, mobile phones. Its application will revolutionize the food industry in near the future.

Antonio, J. et al., 2016. Lamb muscle discrimination using hyperspectral imaging : Comparison of various machine learning algorithms. Journal of Food Engineering, 174, pp.92–100. Available at: http://dx.doi.org/10.1016/j.jfoodeng.2015.11.024.

Abouelkaram, S., Berge, P., & Culioli, J. (1997). Application of ultrasonic data to classify bovine muscles. Proceedings of IEEE Ultrasonics Symposium, 2, 1197–1200.

Abouelkaram, S., Chauvet, S., Strydom, P., Bertrand, D., & Damez, J. L. (2006). Muscle study with multispectral image analysis. In Declan Troy (Ed.), Proceedings of the 52nd International Congress of Meat Science and Technology (pp. 669– 670). Wagening: Wageningen Academic Publishers.

Alomar, D., Gallo, C., Castan˜eda, M., & Fuchslocher, R. (2003). Chemical and discriminant analysis of bovine meat by near infrared reflectance spectroscopy (NIRS). Meat Science, 63, 441–450.

Bannon, D. 2009. Hyperspectral imaging: Cubes and slices. Nat. Photon. 3, 627.

Banović, M., Aguiar Fontes, M., Barreira, M. M., & Grunert, K. G. (2012). Impact of product familiarity on beef quality perception. Agribusiness, 28, 157–172.

Banović, M., Grunert, K. G., Barreira, M. M., & Aguiar Fontes, M. (2009). Beef perception at the point of purchase: A study fromPortugal. Food Quality and Preference, 20, 335–342.

Bredahl, L., Grunert, K. G., & Fertin, C. (1998). Relating consumer perception of pork quality to physical product characteristics. Food Quality and Preference, 9, 273–281.

Chao, K.; Chen, Y.R.; Early, H.; Park, B. (1999) Color image classification systems for poultry viscera inspection. Appl. Eng. Agric., 15, 363–369.

Chau, A., Whitworth, M., Leadley, C., & Millar, S. (2009). Innovative sensors to rapidly and non-destructively determine fish freshness. Seafish Industry Authority. Report No. CMS/REP/110284/1. References 233

Cheng, J. et al., 2016. Developing a multispectral imaging for simultaneous prediction of freshness indicators during chemical spoilage of grass carp fish fillet. Journal of Food Engineering. Available at: http://dx.doi.org/10.1016/j.jfoodeng.2016.02.004.

Cimander, C., Carlsson, M., & Mandenius, C. F. (2002). Sensor fusion for on-line monitoring of yoghurt fermentation. Journal of biotechnology, 99(3), 237-248.

Cluff, K., Naganathan, G. K., Subbiah, J., Lu, R., Calkins, C. R., & Samal, A. (2008). Optical scattering in beef steak to predict tenderness using hyper- spectral imaging in the VIS-NIR region. Sensing and Instrumentation for Food Quality and Safety, 2, 189–196.

Cruz, J.; Bautista, M.; Amigo, J.M.; Blanco, M. (2009), Nir-chemical imaging study of acetylsalicylic acid in commercial tablets. Talanta, 80, 473–478.

Davies, S. (2014). Measurement of crispness in food products using acoustic-mechanical techniques: a literature review.

Delgado, C. L. (2003). Rising consumption of meat and milk in developing countries has created a new food revolution. The Journal of Nutrition, 133(11), 3907S-3910S.

ElMasry, G. & Sun, D., 2010. Principles of Hyperspectral Imaging Technology. Hyperspectral Imaging for Food Quality Analysis and Control, pp.3–43.

FAO, U. (2014). FAOstat. Retrieved Feb, 2014.

FAO 2015, accessed 05.02.2016, http://www.fao.org/ag/againfo/themes/en/meat/home.html

Faucitano, L.; Huff, P.; Teuscher, F.; Gariepy, C., 2005, Wegner, J. Application of computer image analysis to measure pork marbling characteristics. Meat Sci., 69, 537–543.

Font-i-Furnols, M. & Guerrero, L., 2014. Consumer preference, behavior and perception about meat and meat products: An overview. Meat Science, 98(3), pp.361–371. Available at: http://dx.doi.org/10.1016/j.meatsci.2014.06.025.

Food And Agricalture Organization of United States (FAO), Current Worldwide Annual Meat Consumption per capita, Livestock and Fish Primary Equivalent. <http://faostat.fao.org/site/610/DesktopDefault.aspx?PageID=610#ancor>(2013).

Garcia-Allende, P.B.; Conde, O.M.; Mirapeix, J.; Cobo, A., 2008, Lopez-Higuera, J.M. Quality control of industrial processes by combining a hyperspectral sensor and fisher's linear discriminant analysis. Sens. Actuators B Chem., 129, 977– 984.

Gendrin, C.; Roggo, Y.; Collet, C. 2007. Content uniformity of pharmaceutical solid dosage forms by near infrared hyperspectral imaging: A feasibility study. Talanta, 73, 733–741.

Ghasemi-Varnamkhasti, M., Mohtasebi, S. S., Siadat, M., & Balasubramanian, S. (2009). Meat Quality Assessment by Electronic Nose (Machine Olfaction Technology). Sensors (Basel, Switzerland), 9(8), 6058–6083. http://doi.org/10.3390/s90806058

Goetz, A.F.H.; Vane, G.; Solomon, J.E.; Rock, B.N., 1985, Imaging spectrometry for earth remote-sensing. Science, 228, 1147–1153.

He, H. J., & Sun, D. W. (2015). Hyperspectral imaging technology for rapid detection of various microbial contaminants in agricultural and food products.Trends in Food Science & Technology, 46(1), 99-109.

He, H.-J., Wu, D., & Sun, D.-W. (2013). Non-destructive and rapid analysis of moisture distribution in farmed Atlantic salmon (Salmo salar) fillets using visible and near-infrared hyperspectral imaging. Innovative Food Science & Emerging Technologies, 18, 237e245.

He, H.-J.,Wu, D., & Sun, D.-W. (2014a). Potential of hyperspectral imaging combined with chemometric analysis for assessing and visualising tenderness distribution in raw farmed salmon fillets. Journal of Food Engineering, 126, 156e164.

He, H.-J., Wu, D., & Sun, D.-W. (2014b). Rapid and non-destructive determination of drip loss and pH distribution in farmed Atlantic salmon (Salmo salar) fillets using visible and near-infrared (ViseNIR) hyperspectral imaging. Food Chemistry, 156, 394e401.

Huang, H., Liu, L. & Ngadi, M., 2014. Recent Developments in Hyperspectral Imaging for Assessment of Food Quality and Safety. Sensors, 14(4), pp.7248–7276. Available at: http://www.mdpi.com/1424-8220/14/4/7248/.

Huang, H.; Liu, L.; Ngadi, M.O.; Gariepy, C. 2013a. Prediction of pork marbling scores using pattern analysis techniques. Food Control, 31, 224–229.

Huang, M.; Wan, X.; Zhang, M.; Zhu, Q. 2013b. Detection of insect-damaged vegetable soybeans using hyperspectral transmittance image. J. Food Eng., 116, 45–49.

Kamruzzaman, M., ElMasry, G., Sun, D. W., & Allen, P. (2012). Non-destructive prediction and visualization of chemical composition in lamb meat using NIR hyperspectral imaging and multivariate regression. Innovative Food Science & Emerging Technologies, 16, 218-226.

Kamruzzaman, M., Makino, Y. & Oshita, S., 2016a. LWT - Food Science and Technology Hyperspectral imaging for real- time monitoring of water holding capacity in red meat. LWT - Food Science and Technology, 66, pp.685–691. Available at: http://dx.doi.org/10.1016/j.lwt.2015.11.021.

Kamruzzaman, M., Makino, Y. & Oshita, S., 2016b. Parsimonious model development for real-time monitoring of moisture in red meat using hyperspectral imaging. Food Chemistry, 196, pp.1084–1091. Available at: http://dx.doi.org/10.1016/j.foodchem.2015.10.051.

Kim, I.; Kim, M.; Chen, Y.; Kong, S. 2004. Detection of skin tumors on chicken carcasses using hyperspectral fluorescence imaging. Trans. Am. Soc. Agric. Eng., 47, 1785–1792.

Khulal, U. et al., 2016. Nondestructive quantifying total volatile basic nitrogen ( TVB-N ) content in chicken using hyperspectral imaging ( HSI ) technique combined with different data dimension reduction algorithms. , 197, pp.1191–1199.

Lara, M.A.; Lleó, L.; Diezma-Iglesias, B.; Roger, J.M.; Ruiz-Altisent, M. 2013. Monitoring spinach shelf-life with hyperspectral image through packaging films. J. Food Eng., 119, 353–361.

Lim, K. S., & Barigou, M. (2004). X-ray micro-computed tomography of cellular food products. Food research international, 37(10), 1001-1012.

Liu, Y., Lyon, B. G., Windham, W. R., Realini, C. B., Pringle, T. D. D., & Duckett, S. (2003). Prediction of color, texture, and sensory characteristics of beef steaks by visible and near infrared reflectance spectroscopy: a feasibility study. Meat Science, 65, 1107–1115.

Lu, J.; Tan, J.; Shatadal, P.; Gerrard, D.E. 2000. Evaluation of pork color by using computer vision. Meat Sci., 56, 57–60.

Ma, J., Sun, D. & Pu, H., 2016. Spectral absorption index in hyperspectral image analysis for predicting moisture contents in pork longissimus dorsi muscles. , 197, pp.848–854.

Mann, N. (2000). Dietary lean red meat and human evolution. European Journal of Nutrition, 39(2), 71-79.

Marcone, M. F., Wang, S., Albabish, W., Nie, S., Somnarain, D., & Hill, A. (2013). Diverse food-based applications of nuclear magnetic resonance (NMR) technology. Food Research International, 51(2), 729-747.

McAfee, A. J., McSorley, E. M., Cuskelly, G. J., Moss, B. W., Wallace, J. M., Bonham, M. P., & Fearon, A. M. (2010). Red meat consumption: An overview of the risks and benefits. Meat science, 84(1), 1-13.Antonio, J. et al., 2016. Lamb muscle discrimination using hyperspectral imaging : Comparison of various machine learning algorithms. Journal of Food Engineering, 174, pp.92–100. Available at: http://dx.doi.org/10.1016/j.jfoodeng.2015.11.024.

Naganathan, G. K., Grimes, L. M., Subbiah, J., Calkins, C. R., Samal, A., & Meyer, G. E. (2008a). Visible/near-infrared hyperspectral imaging for beef tenderness prediction. Computers and Electronics in Agriculture, 64(2), 225–233.

Naganathan, G. K., Grimes, L. M., Subbiah, J., Calkins, C. R., Samal, A., & Meyer, G. E. (2008b). Partial least squares analysis of near-infrared hyper- spectral images for beef tenderness prediction. Sensing and Instrumentation for Food Quality and Safety, 2, 178–188.

Nagata, M.; Tallada, J.G.; Kobayashi, T. 2006, Bruise detection using nir hyperspectral imaging for strawberry (fragaria x ananassa duch.). Environ. Control Biol., 44, 133.

Neumann, C. G., Murphy, S. P., Gewa, C., Grillenberger, M., & Bwibo, N. O. (2007). Meat supplementation improves growth, cognitive, and behavioral outcomes in Kenyan children. the Journal of Nutrition, 137(4), 1119-1123.

Osborne, B. G. 2006. Near-Infrared Spectroscopy in Food Analysis. Encyclopedia of Analytical Chemistry (Book), John Wiley & Sons, Ltd, 2006

O'sullivan, M.G.; Byrne, D.V.; Martens, H.; Gidskehaug, L.H.; Andersen, H.J.; Martens, M. 2003. Evaluation of pork colour: Prediction of visual sensory quality of meat from instrumental and computer vision methods of colour analysis. Meat Sci., 65, 909–918.

Park, B., Lawrence, K. C., Windham, W. R., & Smith, D. P. (2006). Performance of hyperspectral imaging system for poultry surface fecal contaminant detection. Journal of Food Engineering, 75(3), 340-348.

Patel KK, Kar A, Jha SN, Khan MA. 2012, Machine vision system: a tool for quality inspection of food and agricultural products. Journal of food science and technology.;49(2):123-141. doi:10.1007/s13197-011-0321-4.

Qiao, J., Ngadi, M. O., Wang, N., Gariepy, C., & Prasher, S. O. (2007a). Pork quality and marbling level assessment using a hyperspectral imaging system. Journal of Food Engineering, 83(1), 10–16.

Qiao, J., Ngadi, M.,Wang, N., Gunenc, A., Monroy, M., Gariepy, C., & Prasher, S. (2007b). Pork quality classification using a hyperspectral imaging system and neural network. International Journal of Food Engineering, 3(1). Article No. 6.

Qin, J., Ying, Y., & Xie, L. (2013). The detection of agricultural products and food using terahertz spectroscopy: A review. Applied Spectroscopy Reviews,48(6), 439-457.

Segtnan, V. H., Høy, M., Lundby, F., Narum, B., & Wold, J. P. (2009). Fat distribution analysis in salmon using non-contact near infrared interactance imaging: a sampling and calibration strategy. Journal of Near Infrared Spectroscopy, 17, 247e253.

Shackelford, S. D., Wheeler, T. L., & Koohmaraie, M. (2004). Development of optimal protocol for visible and near-infrared reflectance spectroscopic evaluation of meat quality. Meat Science, 68, 371–381.

Shackelford, S. D., Wheeler, T. L., & Koohmaraie, M. (2005). On-line classification of US select beef carcasses for longissimus tenderness using visible and near-infrared reflectance spectroscopy. Meat Science, 69(3), 409–415.

Sun, D.-W. (2010). Hyperspectral imaging for food quality analysis and control. San Diego, California, USA: Academic Press/Elsevier.

Tan, J.L. 2004. Meat quality evaluation by computer vision. J. Food Eng., 61, 27–35.

Todd, E. C. (1996). Epidemiology of foodborne diseases: a worldwide review. World health statistics quarterly. Rapport trimestriel de statistiques sanitaires mondiales, 50(1-2), 30-50.

Verbeke, W., De Smet, S., Vackier, I., Van Oeckel, M. J., Warnants, N., & Van Kenhove, P. (2005). Role of intrinsic search cues in the formation of consumer preferences and choice for pork chops. Meat Science, 69, 343–354.

Vote, D. J., Belk, K. E., Tatum, J. D., Scanga, J. A., & Smith, G. C. (2003). Online prediction of beef tenderness using a computer vision system equipped with a BeefCam module. Journal of Animal Science, 81, 457–465.

Webb, K., Rutishauser, I., Katz, T., Knezevic, N., Lahti‐Koski, M., Peat, J., & Mihrshahi, S. (2005). Meat consumption among 18‐month‐old children participating in the Childhood Asthma Prevention Study. Nutrition & Dietetics, 62(1), 12-20.

West, G. E., Larue, B., Touil, C., & Scott, S. L. (2001). The perceived importance of veal meat attributes in consumer choice decisions. Agribusiness, 17, 365–382.

WHO 2016http://www.who.int/mediacentre/factsheets/fs399/en/.» Food Safety. December 2015.

http://www.who.int/mediacentre/factsheets/fs399/en/ (accessed: 02 01, 2016).

Wold, J. P., Johansen, T., Haugholt, K. H., Tschudi, J., Thielemann, J., Segtnan, V. H., Narum, B., & Wold, E. (2006). Non- contact transflectance near infrared imaging for representative on-line sampling of dried salted coalfish (bacalao). Journal of Near Infrared Spectroscopy, 14(1), 59–66.

Wu, Di, Sun, Da-Wen, & He, Yong (Oct 2012). Application of long-wave near infrared hyperspectral imaging for measurement of color distribution in salmon fillet. Innovative Food Science & Emerging Technologies, 16, 361e372.

Xing, J.; Bravo, C.; Jancsók, P.T.; Ramon, H.; de Baerdemaeker, J. 2005. Detecting bruises on „golden delicious‟ apples using hyperspectral imaging with multiple wavebands. Biosyst. Eng., 90, 27–36.

Yao, H.; Hruska, Z.; Kincaid, R.; Brown, R.L.; Bhatnagar, D.; Cleveland, T.E. 2013. Detecting maize inoculated with toxigenic and atoxigenic fungal strains with fluorescence hyperspectral imagery. Biosyst. Eng., 115, 125–135.

Zaragozá, P. et al., 2012. Fish freshness decay measurement with a colorimetric array. Procedia Engineering, 47, pp.1362– 1365. Available at: http://dx.doi.org/10.1016/j.proeng.2012.09.409.

Zheng, J., & He, L. (2014). Surface‐Enhanced Raman Spectroscopy for the Chemical Analysis of Food. Comprehensive Reviews in Food Science and Food Safety, 13(3), 317-328.

LABSİS GİRİŞ

ANALİZ TALEBİ